Analysis of Factors Affecting the Productivity of Seed Processing Equipment

- Categories:NEWS

- Author:Jason Wei

- Origin:Sanli

- Time of issue:2022-07-11

- Views:888

(Summary description)This article will focus on briefly analyze several main factors that affect the productivity of seed equipment processing.

Analysis of Factors Affecting the Productivity of Seed Processing Equipment

(Summary description)This article will focus on briefly analyze several main factors that affect the productivity of seed equipment processing.

- Categories:NEWS

- Author:Jason Wei

- Origin:Sanli

- Time of issue:2022-07-11

- Views:888

As a supplier of grain processing equipment, we often encounter customers and friends who ask us, "Why do the same processing machinery processing different crops with different capacity?" Why the machine have same sieve area, some factory’s machine capacity is big, but some factory’s capacity is smaller?”; “Why some suppliers ask me a lot of questions when I consult the processing capacity of suppliers, such as moisture content, impurity content, etc.”

This article will focus on the above problems and briefly analyze several main factors that affect the productivity of seed equipment processing.

Ⅰ. Crop bulk density affect the capacity of equipment

Bulk density is the weight of a material per unit volume. In agricultural crops, "g/L" is usually used as the unit of bulk density.

Seed processing equipment, regardless of its own feeding bucket, sieve surface or various types of conveying and lifting equipment, adopts a certain volume of bucket or sieve bed as the feeding and screening bearing device, so the bulk density is the most important factor of seed processing production.

Generally speaking, when other factors of the crop are the same or similar (such as: moisture, 1000-grain weight, impurity content, etc.), the bigger the bulk density, the bigger the processing capacity of the seed equipment, and vice versa.

Ⅱ. Seed Processing Machine itself affect the capacity

Seed processing equipment is agricultural field operation machinery. Our company mainly produces equipment such as shelling/threshing/awn removal, impurity separation and sorting, and seed coating. Here, I will focus on the equipment itself factors on capacity in the separation and sorting process.

According to the performance of the equipment and the function of removing impurities, the sorting equipment mainly includes air screen cleaners, gravity separator, combination seed cleaner (air screen cleaner and gravity table integrated machine), gravity De-stoner, vibrating screen, belt sorter, magnetic separator, polishing machine, grading machine and color sorter, etc. And these machines will be derived from many different models according to the processing capacity, structural characteristics, etc.

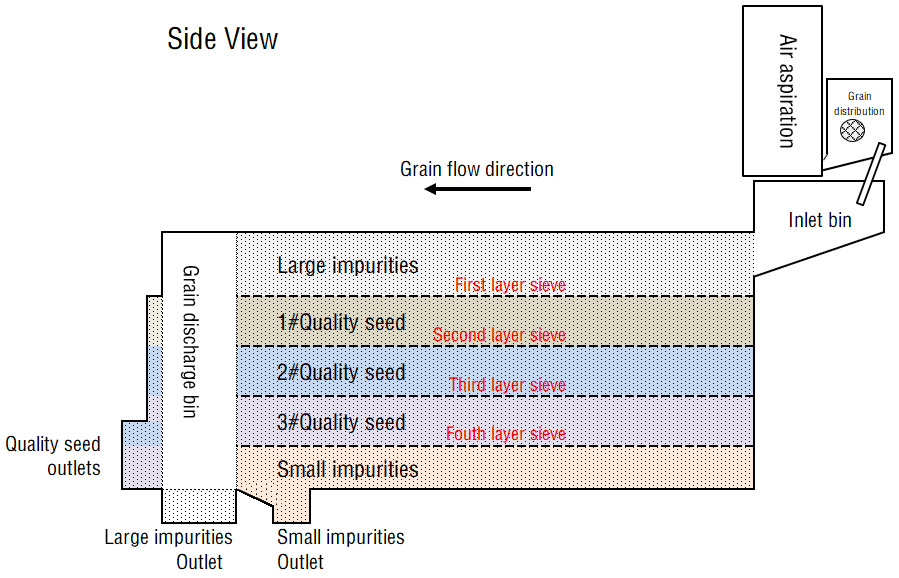

Generally speaking, the newly harvested crops will contain a lot of impurities, such as light impurities, large impurities and small impurities. Therefore, the air screen cleaner is often used as the first process of the complete set of seed processing equipment. As a primary cleaning machine, its processing capacity and cleaning effect directly determine the working status of the subsequent processing equipment, so this article will focus on the air screen cleaner.

Take our company's 5XZC series air screen cleaner as an example, its structure mainly includes lifting device, air separation device, bulk grain device, screening device, electric control device and walking device. The main parts that affect the capacity of the equipment are the lifting device, the bulk grain device and the screening device.

1. The effect of lifting devices on equipment capacity

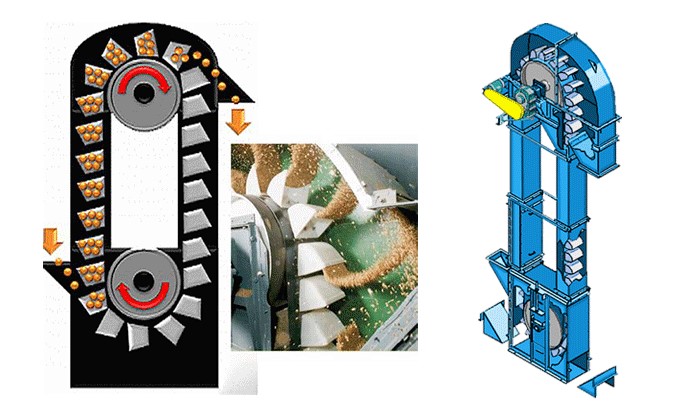

Our company's standard 5XZC series cleaning machine is mainly equipped with a bucket elevator, which is mainly driven by a motor to drive the belt to rotate. After the material is transported to a certain height through the bucket on the belt, the material is dumped to the conveyor in the grain pipeline. According to the processing capacity, our company's 5XZC series cleaning machines mainly include 3 types, 5 types, 7.5 types and 15 types. The processing capacity increases in turn. For different types of cleaning machines, we will install bucket elevators that match the processing capacity machine.

The two main factors that affect the capacity of the bucket elevator are the speed of the motor and the capacity of the bucket on the belt. The faster the motor speed, the bigger the amount of lifting; and the bigger of the bucket elevator capacity. Of course, it is not so absolute,some manufacturers do not grasp the relationship between speed and capacity. Although their motor speed is fast and the bucket is also large, their lifting capacity has not increased proportionally. This is because at the feeding end, the flow rate of the material is constant. If the linear speed of the belt is too fast, the material will not have enough time to enter the bucket, so that no matter how big the bucket is, more materials cannot flow into it, even the speed is very fast, the material flowing into the bucket is even less than that of the elevator with a relatively small speed.

The above are all factors of the equipment itself. As a manufacturer of seed processing equipment, we have nearly 30 years of R&D and production experience. Please feel free to use it. In addition to the reasons for the design and machine itself, many customers and friends will ask, "Why is the lifting capacity not as much as before?" We can find solutions from the following aspects.

1-1. Check the tension of the elevator belt

When the elevator is working, the bucket on the feeding side is loaded with materials; while the bucket on the discharging side is empty after unloading. After a long time of work, due to the uneven force, the elevator belt will be stretched to a certain extent, which may cause the belt to slip or deflect on the driving pulley, there by reducing the linear speed of the belt, resulting in reduce the lifting amount.

Solution: Stop the machine, adjust the upper and lower belts, and then adjust the adjustment screws on the base of the elevator to make the belt and the driving wheel closely fit.

1-2. Check the elevator belt and bucket for foreign objects

Because the raw materials contain many impurities, including wooden sticks, large stones, twine and so on. These impurities will jam the bucket and cause the belt to slip, and if the impurities are heavy, the bucket and the belt will be torn.

Solution: Shut down, remove these impurities.

1-3. Check if the elevator belt and bucket is damage

The existence of foreign objects or the deflection of the elevator belt will cause damage to the belt, and even the bucket will be scratched. This will affect the lifting capacity of the elevator. In this case, we need to replace the elevator belt and bucket to restore the normal workload.

2. Bulk Grain Device on Equipment Capacity

After the material is conveyed by the bucket elevator, before entering the air separation device, it will flow through the conveying pipe and the bulk grain tank. If this part is not handled properly, it will also affect the processing capacity. Some materials, such as cumin and grass seeds, have poor flow, and the raw materials contain many stems, branches and other rods, which are easy to accumulate in the conveying pipe and slow down the conveying. This requires us to speed up the flow by increasing the cross-sectional area of the feeding pipe or changing its inclination. Once again, if the capacity is found to slow down, it is also necessary to check the bulk grain box to see if the material is conveyed evenly. Our company air screen cleaner has a plug at the lower end of the conveying pipe. By adjusting the position of the plug, the uniformity of the bulk grain of the material can be adjusted. The material can enter the follow-up air selection and screen surface evenly, so as to avoid material accumulation and blockage and the reduction of capacity caused by it.

3. The influence of Vibrating Screen on equipment capacity

3-1. Increase capacity by adjusting the inclination of the screen box

Adjusting the inclination of the screen box can speed up the flow of materials inside the screen box, thereby increasing the output. As shown in the below, move the fixed plates on both sides of the screen box close to the up a certain distance. Please note that the fixed plates on both sides must be kept at the same height (one side cannot be high and the other side is low). You can move up 3-5cm first to see the effect, and then decide whether you need to continue to improve.

Here, it should be noted that the inclination of the screen box cannot be adjusted too large, otherwise the spring rubber will be unstable, and the screening effect of the material will be greatly affected. Our company's screen box inclination can basically meet the clarity standard of seed screening.

From the above photo, we can clearly see the difference between the two screen box inclination angles. For example, in the case of the same screen surface size, the inclination angle of the screen box on the left is relatively large. The advantage is that the flow speed of the material is fast and the productivity is high; It is suitable for the primary selection of crops or company that do not require high screening clarity. The inclination angle of the vibrating screen on the right is relatively small, the material flow is relatively slow, and the material can have enough time to be screened. It is used by seed industry or the company with higher sorting requirements.

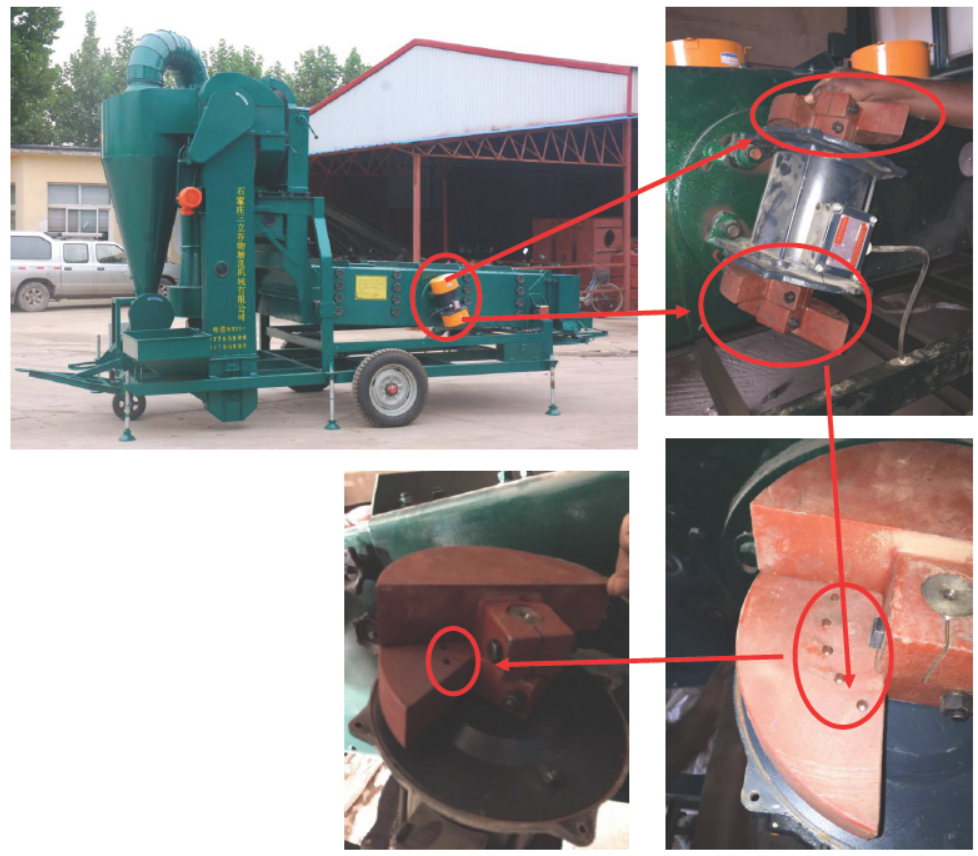

3-2. Increase productivity by adjusting vibration frequency

By adjusting the vibration amplitude of the vibration motor, the flow speed of the material can also be changed, thereby changing the processing capacity of the equipment.

Steps to increase the amplitude:

1)Open the upper and lower end covers of the vibration motor.

2)Check that the eccentric block currently exposes several positioning holes.

3)If 5 positioning holes are exposed, loosen the locking screw of the outer eccentric block and separate it from the inner eccentric block. Move the outer eccentric block to adjust its positioning pins into the appropriate positioning holes to expose 3 positioning holes. Check the processing effect, If also feel that the processing capacity is small, so only one positioning hole can be exposed to see if the processing capacity is satisfactory.

If 2 positioning holes are initially exposed, adjust the position of the lower outer eccentric block so that 1 positioning hole is exposed, and see how the effect is. If it feels slow, you can make the inner and outer eccentric blocks coincide, and then check whether the processing capacity is satisfactory.

Please note that:

A: For the same motor, the position of the upper and lower eccentric blocks must be the same, that is, several positioning holes are exposed on the upper side, and several positioning holes must also be exposed on the lower eccentric block.

B: The eccentric blocks of the motors on both sides should also be consistent, that is, the left motor eccentric block must expose several positioning holes, and the right motor eccentric block must also expose several positioning holes.

C: The fewer positioning holes exposed by the eccentric block, the larger the amplitude, and the higher the output; the more positioning holes exposed by the eccentric block, the smaller the amplitude, and the lower the output.

3-3. Change capacity by adjusting the hole size of the screen

The screen is the core component of the cleaning machine, and the accuracy of the screen aperture setting plays a key role in the screening clarity and processing capacity of the cleaning machine.

1)Different types of materials, the effect of the aperture of the screen on the processing capacity

Taking wheat and sesame as an example, if other factors are the same, the bulk density of wheat is 790g/L, the bulk density of sesame is 550g/L, and the bulk density ratio of the two crops is 1:0.7. In principle, if the wheat processing capacity of the cleaning machine is 10 tons/hour, the processing sesame should be able to reach 7 tons/hour, but in fact, the processing of sesame is often not even 3 tons/hour. There are many reasons, excluding other influencing factors (the poor fluidity of sesame, high impurity content, etc.), the aperture of the sieve is also an important factor affecting the processing capacity.

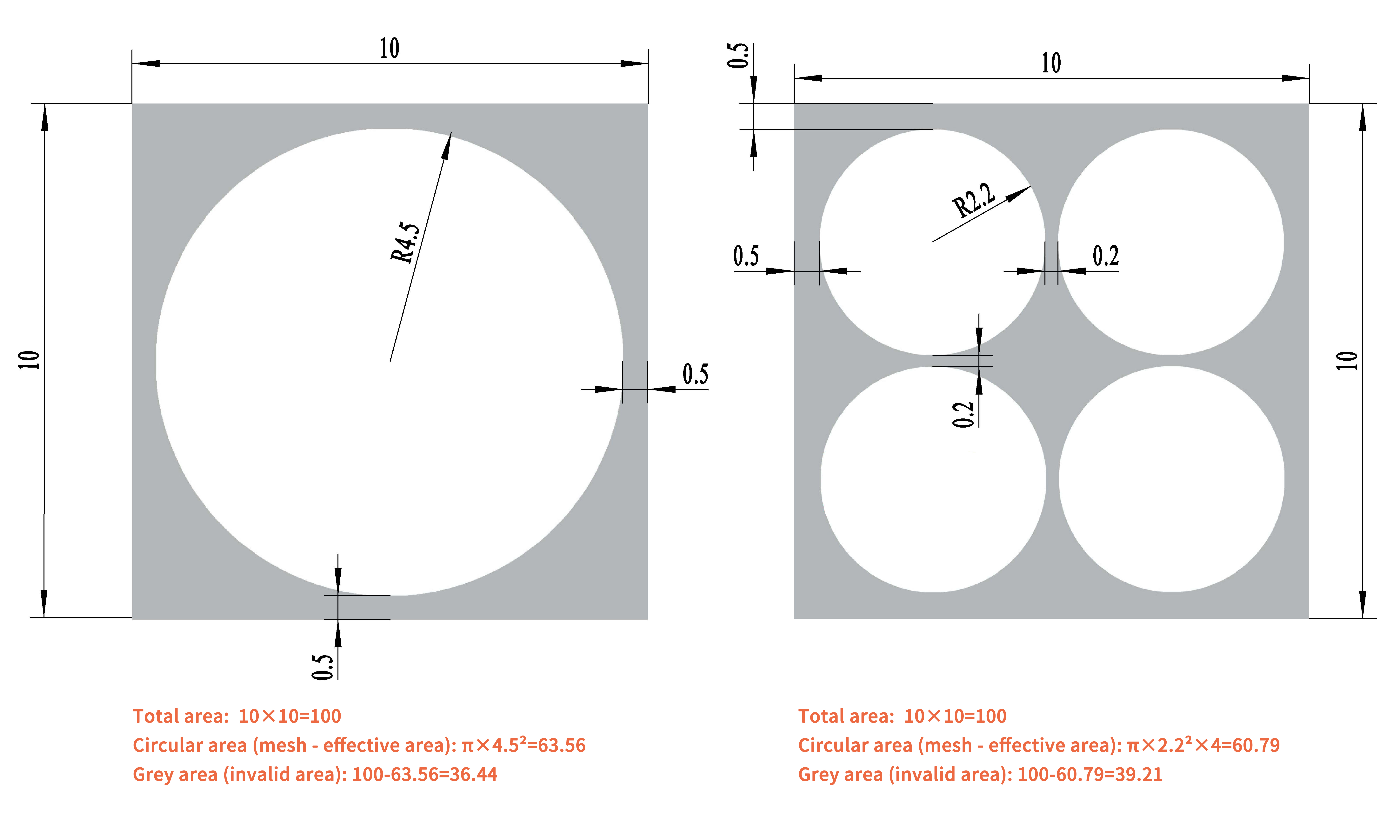

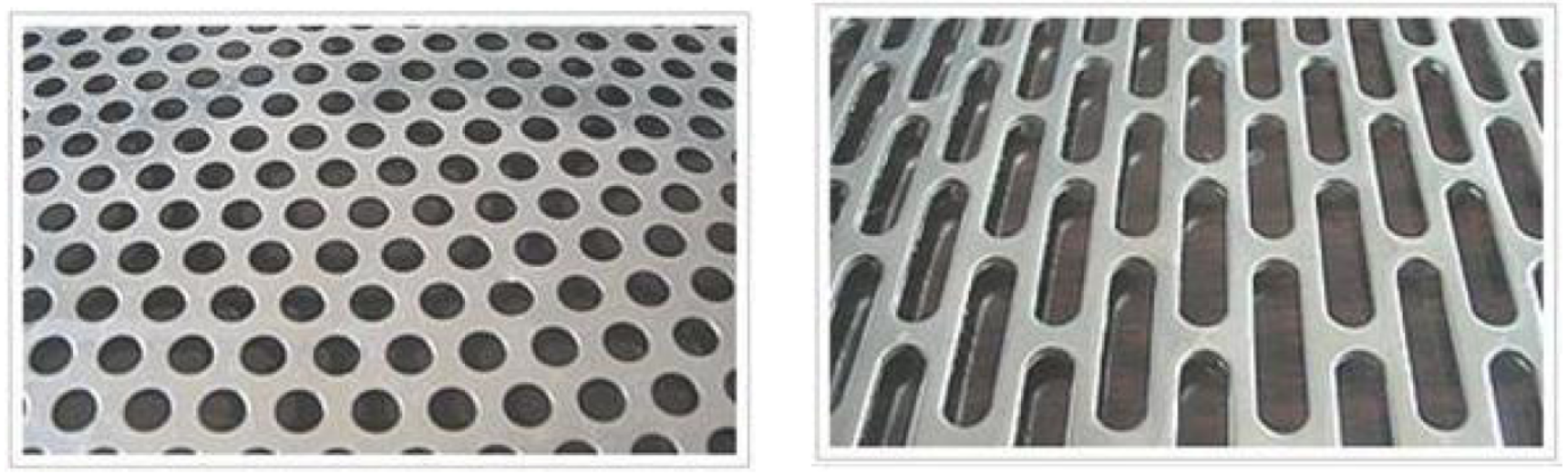

We all know that why the screen can screen crops is because there are many holes on the screen, and these holes are the effective area of the screen. Please see the photo below, we use an extreme example to briefly understand the effective area of the screen.

Referring to the left and right pictures above, assume that this is a screen with both sides of 10 units. In the picture on the left, we can draw a circle with a maximum radius of 4.5 units, and in the picture on the right, we can draw four circles with a maximum radius of 2.2 units. The holes should not be close to the four sides of the screen, and there should be enough clearance between the round hole and the round hole).

Through calculation, the screen area (effective area) of the left screen is 63.56, while the total area (effective area) of the four screen holes of the right screen is only 60.79. By analogy, we can get a conclusion: the more punching holes and the smaller the aperture, the smaller the effective area of the screen of the same size, which means the lower the permeability of the screen.

The shape of sesame is much smaller than wheat, so the aperture of sieve will be much smaller. In this way, we can understand very well that although the bulk density of sesame is 70% of that of wheat, but the actual capacity of processing sesame is less than 30% of wheat.

2)For the same kind of materials, the effect of the aperture of the sieve on the processing capacity

A: If there is no good material in the large impurities, and the good material can pass through the upper screen very smoothly, there is no need to adjust the aperture of the screen to remove the large impurities. Conversely, can increase the aperture to increase the capacity.

B: Decreasing the aperture size of the main product, this can improve the capacity. However, please use it with caution, because reducing the aperture of the screen may cause small impurities to pass through the screen smoothly, resulting in the mixture of small impurities in the main material.

To sum up, judging the capacity of one equipment to process a certain crop is a relatively complex problem. Only who with rich theoretical knowledge and industry experience can give a relatively accurate answer. When a customer inquiries about the processing capacity, the sales from some manufacturers often exaggerate the capacity of their equipment to meet the needs of customers for the purpose of selling their equipment. This is an extremely irresponsible behavior, which will affect the efficiency of the entire production line due to the mismatch of processing capacity. I hope that our customers and friends will conduct multiple inspections and comparisons when purchasing seeds processing equipment, so can find the most suitable equipment.

Shijiazhuang Sanli Grain Sorting Machinery Co.,Ltd. has 30 years of experience in the research and development for producing of grain processing equipment. As an important manufacturer seed machinery industry in the domestic, we will adhere to the spirit of "Sanli" - determination, morality, and innovation, will provide reliable quality products and excellent service. Welcome friends to visit our factory and give conduction.

Scan the QR code to read on your phone

CONTACT US

Tel: 0086-311-87711446

Fax: 0086-311-66635737

WeChat: jasonwei6686

E-mail: marketing@sanli.net.cn

ADD.: Room810,Xiushui Building, 363# North of Zhonghua Str. Shijiazhuang City, Hebei Province, China P.R