OUR PRODUCTS

OUR PRODUCTS

Number of views:

1000

PG-5D Bean polisher

Retail price

0.0

Yuan

Market price

0.0

Yuan

Number of views:

1000

Product serial number

dl1011

Quantity

-

+

Stock:

Description

Parameters

PG-5D Bean polisher

Brief Instruction

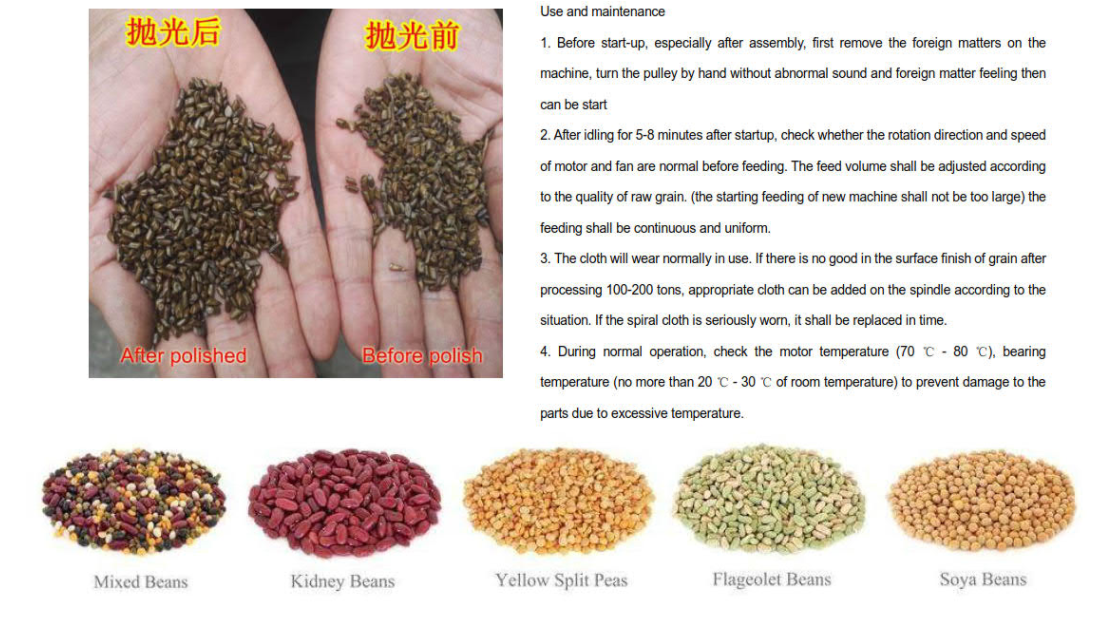

Bean polisher, also known as grain polisher, is based on the rotation of the spiral axis to make the grains displace each other in the process of fluidization and friction with the cotton cloth fixed on the spiral axis, so that the grains can achieve an ideal polishing effect.

It is mainly used in seed processing and agricultural product processing industries, and has good polishing effect on beans, wheat, rice, grains, corn, etc., especially better for the sorted beans, grains, corn. The products processed by the bean polishing machine are bright and clear with good surface finish, which further improves the quality of grains. The blowing type bean polisher (PG-5D model) adopts the frequency conversion and wind circulation system, which can adjust the rotation frequency of the machine, so that the grains can be polished at the most appropriate frequency in the equipment to achieve the maximum polishing effect, and the dust, impurities and mildew on the surface can be removed to make the grains have the perfect glossiness.

This equipment can polish all kinds of grains. It has the function of one machine and multi-purpose. It is easy to operate and environmental friendly.

Technical specification

|

Model |

Capacity |

Power |

Size(L×W×H) mm |

Weight Kg |

Re-mark |

|

PG-5 |

3-5T/h |

7.7 kW/380V |

3200×620×1700 |

450 |

Single cylinder |

|

PG-5D |

11 kW/380V |

3400×700×2000 |

600 |

Single cylinder |

|

|

PG-5DT |

22 kW/380V |

3500×1150×2800 |

1100 |

Double cylinder |

Note: The capacities may vary depending on grains condition, moisture content, grain varieties, types and volumes of contaminants to be separated and percentage of foreign material acceptable in the final product.

Keyword:

bean polishing machine

seed polisher

grain polishing mahcine

Scan the QR code to read on your phone

Previous

PG-5DT Bean polisher

CONTACT US

Tel: 0086-311-87711446

Fax: 0086-311-66635737

WeChat: jasonwei6686

E-mail: marketing@sanli.net.cn

ADD.: Room810,Xiushui Building, 363# North of Zhonghua Str. Shijiazhuang City, Hebei Province, China P.R