OUR PRODUCTS

Z Type Bucket Elevator

Z Type Bucket Elevator

Product introduction

Z-type rotary bucket elevator has obvious advantages such as large conveying capacity, high lifting height, stable and reliable operation, long service life and so on.It is suitable for conveying powdery, granular and small pieces materials. At present, it is mostly used for feeding of weighing and packaging machine, feeding and re-feeding of color sorter, and three-dimensional cycling feeding and unloading of automatic production line.

Our products are currently operating normally in the following automatic production industries: seed processing industry, grain finishing industry, health food industry, expanded food industry, feed industry, candy industry, fresh and dry fruit industry, PVC granules, pet food industry, chemical and pharmaceutical industry and so on.

Product characteristics

1.Sealing operation is pollution-free, the whole machine shell is sealed, there is no leakage during operation, no dust flying, to meet the requirements of environmental protection.

2.To prevent material overflow, it can be equipped with vibrating feeder and uniform feeding with inflow type, which overcomes the phenomenon of full hopper overflow.

3.To prevent material damage, the whole process of feeding, conveying and unloading has no damage to the object itself and reduces the waste rate.

4.Wide range of lifting, less requirements for the types and characteristics of materials. It can not only improve the general powder and small granular material, but also enhance the material with larger grinding ability.

5.Good operation reliability, advanced design principles and processing methods ensure the reliability of the whole machine operation, fault-free time more than 30,000 hours.

6.Long service life, the feeding of the hoist adopts the inflow type, without the need for bucket excavation, and there are few extrusion and collision between materials.

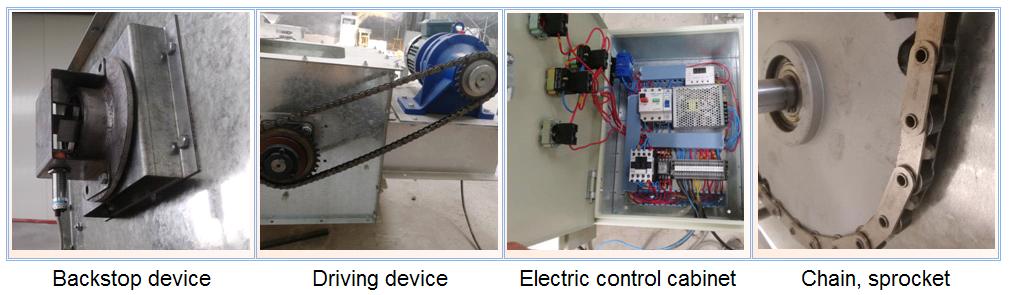

7.It is equipped with backstop device to prevent the hoist from reversing after the equipment stops running due to power failure or other factors.

Working principle

When working, the reducer motor drives two sprockets to move synchronously through bearings, so that the two chains meshing with it move synchronously on the closed track. When the material is transported to the hopper, it slips into the hopper forward horizontally, and then the excess material in the hopper is brushed into the next hopper by the brush of the feeder. Because the material slips into the hopper, it is not forced to scrape, so the material will not be broken. In this way, the hopper between the two chains moves continuously on its closed track through the synchronous movement of the two chains. Under the action of the turning wheel, the hopper turns over, and the material in the hopper falls into the temporary storage bin of the equipment matched with it from the outlet of the hoist.

Specification parameter

|

Model |

Capacity (60% bucket volume) |

Height (m) |

Power (kW) |

Discharge out Quantity |

|

5T-15 |

9 m3/h |

2-15 |

0.75-1.5 |

1 |

|

5T-20 |

12 m3/h |

2-15 |

0.75-1.5 |

1-10 |

|

5T-30 |

18 m3/h |

2-15 |

2.2-3 |

1-10 |

You can customize it if you have special requirements.

According to your material name, the output per hour, the height (the distance from the outlet to the ground), the upper and lower horizontal distance can choose the model.

CONTACT US

Tel: 0086-311-87711446

Fax: 0086-311-66635737

WeChat: jasonwei6686

E-mail: marketing@sanli.net.cn

ADD.: Room810,Xiushui Building, 363# North of Zhonghua Str. Shijiazhuang City, Hebei Province, China P.R